Product Quality Control & Inspection Services in Malaysia

Avoid unpleasant surprises by sending an expert on-site for a full quality control of your products. We ensure that defects are corrected at your supplier’s expense.

1 in 5 products manufactured in Asia doesn’t meet international quality standards.

Are you willing to take the risk?

A quality inspection is designed to confirm that your products are manufactured exactly as specified. At each stage of production, our inspectors verify compliance directly at the supplier’s site in Malaysia, ensuring no defective or non-compliant products are shipped.

This process is critical to prevent losses, guarantee customer satisfaction, and protect your supply chain.

Without quality control

- Defects go unnoticed until it’s too late

- Expensive product returns and customer complaints

- Shipments blocked at customs for non-compliance

- No leverage on suppliers once goods are shipped

With quality control

- Issues identified before shipping

- Suppliers fix problems before final payment

- Products aligned with your standards & destination regulations

- Peace of mind and satisfied customers

Experts on-site to guarantee quality

Our inspectors travel directly to Malaysian factories, in Penang, Kuala Lumpur, Johor, or beyond, to supervise production and verify specifications. You get complete visibility without needing to be there yourself.

We protect your interests, always

If your products don’t match requirements, we ensure the supplier fixes them before shipping. Nothing leaves the factory until it meets your standards, we act as your eyes and ears on the ground

Inspections aligned with your country’s regulations

We apply international inspection standards (ISO 2859-1, ANSI/ASQC Z1.4-2003). Using AQL tables, we perform random sampling and classify defects as critical, major, or minor. We also adapt inspections to industry-specific needs, including Halal requirements, CE markings, or electrical safety testing.

Pay only when everything is approved

With DocShipper Malaysia, you only pay for products that pass inspection.

If issues are found, we coordinate with the supplier until corrections are made and validated.

Let’s make sure you’re getting exactly what you’re paying for.

Ensure the quality of your orders in China. Book an on-site inspection today.

Clients Testimonials

We can't make this up, read why businesses are trusting us with their international sourcing every day.

I own a small custom furniture startup. I recently needed to import some materials from China and worked with DocShipper for the first time. Honestly, they made the whole process way simpler than I expected. My contact was super helpful, always checking in and answering my questions. It was my first import, so I was worried things would go wrong, but they handled it all like pros. Highly recommend!

Thomas Brecht

January 9, 2025My name is Ad Van Den Bosh. I am a Dutch business man cross-trading in the Far East. I reached Robert Houwayek to clear a 40HC of greenhouse equipment from Qingdao, and deliver it to Lan Krabue in no time. He suggested that I request a Form E, which I did from the supplier, and was able to enjoy a preferential tariff treatment. DocShipper, a way to help you save both time and money!

Ad van den Bosch

March 5, 2024Starting a sound book publishing business wasn’t easy. I had no experience sourcing from China, but Daniel from DocShipper made it possible. He took care of everything, finding a factory, production, quality even negotiating better deals than I imagined!! He explained things clearly and eased my stress. Thanks to DocShipper, the whole process went smoothly. I’m excited to work with them again in the near future!

Grace O’Donnell

October 13, 2024As a small fashion business owner, I was nervous importing my new collection from a new supplier. I didn’t know what to expect, bu they explained every step and answered all my questions without any condescension. The team was patient, knowledgeable, and efficient. The goods arrived on time and exactly like the sample. I’m so happy with how things went and will definitely rely on them for future imports.

Jasmine Nguyen

January 5, 2025A vice president caught up in the thick of thin things, an EXW shipment of plumbing supplies for irrigation from Eureka California to Caldera Costa Rica is definitely not what I’d like to have on my agenda. [...]This time he skillfully handled all US export formalities incl. SED/AES filing, pre-pull drayage, not to mention the sea freight from Oakland POL by a 20-footer. Everything ended up working out like a charm!

Dave Sheppard

July 10, 2024DocShipper shipped a 20- ft Milvan overseas to Laem Chabang for a customer. The team was responsible for shipping the shipping to another country. Having very little knowledge in this area, I didn't know how to organise myself . One week after my arrival on the Asian continent. Marc O. Was available at all times and nearly instant feedback. Made a stressful event much easier and he definitely knows his job.

Anonymous, Indiana

Aug 9, 2023The 5 Key Steps of our Quality Control Process

We follow a simple and efficient process with clear steps to keep you informed at every moment, ensuring your products meet your expectations before leaving the factory.

Pre-production consultation

We review your specifications and secure supplier commitment with a 30% deposit before production starts.

DPI (During Production Inspection)

Our inspectors visit the factory mid-production to ensure compliance with requirements and detect defects early.

PSI (Pre-Shipment Inspection)

Once production is complete, we check product quality, labeling, and packaging before shipment.

Balance payment after PSI validation

You pay the remaining 70% only once the inspection report is approved, no risk of paying for defective goods.

CLS (Container Loading Supervision)

We monitor container loading to ensure goods are correctly packaged, stacked, and secured for transport.

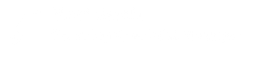

What Will You Find in Your Inspection Report?

The audit report you receive is a detailed document covering all essential aspects of your supplier. It is divided into several key sections to provide you with a comprehensive overview of the supplier’s qualifications and ability to meet your expectations.

The inspection report begins with a complete summary of the product and the site where the inspection was carried out. It specifies the product description, the factory or warehouse location, and the exact quantity ordered and inspected. It also details the inspection method applied, such as ANSI/ASQ Z1.4 procedures, and provides an overall conclusion, stating whether the order has passed the inspection or if corrections are required before shipment.

All defects detected during the inspection are classified into three categories: critical, major, or minor. Each defect is described in detail and accompanied by photos for visual proof. Whether it is scratches, marks, assembly errors, or non-compliant labeling, the report outlines exactly what was found and includes recommendations for how these issues should be addressed, whether through repairs, rework, or a complete re-manufacturing process.

The inspection includes functional testing to ensure that the product performs according to specifications. Assembly tests confirm that items can be put together correctly, while load tests measure the resistance and strength of the product under stress. Functional tests validate overall performance, such as proper operation of switches, lights, or moving parts. Flow tests, when applicable, simulate real usage conditions to check performance under actual operating scenarios.

Our inspectors also verify that the quantities produced match the quantities ordered. This includes comparing ordered and delivered units and analyzing packaging specifications such as the number of products per carton, the dimensions of cartons, and their weight. These checks ensure that your order not only meets quality standards but also aligns with logistical requirements for transport and storage.

The report provides a full visual overview of the products inspected, with photos taken from different angles. Images of the cartons and their labeling are also included, giving you clear confirmation of compliance with packaging and marking requirements before your goods are shipped.

Precise measurements of each product and its packaging are included, confirming that the items match the specifications in terms of size and weight. Both net and gross weights are verified, ensuring accuracy for customs declarations, transport, and handling.

To ensure objectivity, inspections are carried out according to international AQL standards. The report presents the tolerance levels applied and the exact number of defects found within those limits. This gives you a transparent and unbiased result that aligns with international quality standards.

Finally, the report concludes with the inspector’s notes and professional recommendations. These comments may include actions that should be taken immediately, as well as advice to improve the quality of future productions or shipments. This section ensures that you not only get a snapshot of the current order but also guidance for optimizing future collaborations with your suppliers.

Download a Sample Inspection Report

Download a full report sample to see how we analyze and evaluate your suppliers.

Have questions? We

have answers

Ask Questions.

Get clear answer.

Sourcing is a big decision that requires careful research and attention to detail. If you’re unsure or have questions, schedule a free consultation with our experts—we’ll provide honest guidance, no commitment needed.